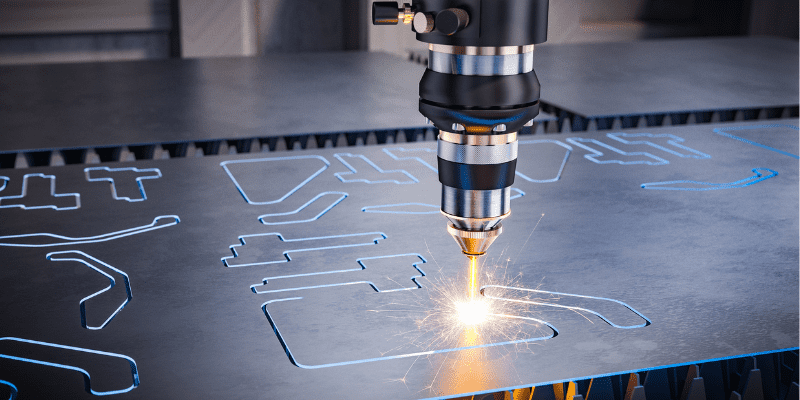

Modern manufacturing relies on tools that deliver microscopic precision for creating intricate components, such as medical implants and passenger jet parts. Laser cutting technology excels in meeting these demands, offering a powerful solution for producing complex parts with exceptional detail.

The Science Behind a Perfect Cut

At its core, laser cutting is a thermal process that uses a highly focused, high-energy beam of light to melt, burn, or vaporize material in a specific path. The term “laser” is an acronym for Light Amplification by Stimulated Emission of Radiation. This process creates a concentrated beam of light that can be directed and controlled with extreme precision.

How Does It Work?

The process begins with a laser generator creating the beam. This beam is then directed through a series of mirrors and lenses to a cutting head. The cutting head focuses the laser onto a very small spot on the workpiece. The intense heat generated at this focal point causes the material to melt or vaporize. Simultaneously, a jet of assist gas, such as oxygen, nitrogen, or compressed air, is blown through a nozzle concentric with the laser beam. This gas helps to clear away the molten material, or “kerf,” leaving a clean, smooth edge.

There are several types of lasers used in manufacturing, each suited for different materials and applications:

- CO2 Lasers: These are among the most common types and use a gas mixture (primarily carbon dioxide) to produce the laser beam. They are highly efficient and are excellent for cutting non-metallic materials like wood, acrylic, plastic, and leather, as well as thin sheets of metal.

- Fiber Lasers: These solid-state lasers use optical fibers doped with rare-earth elements. Fiber lasers are known for their high power, excellent beam quality, and low maintenance. They are particularly effective for cutting and engraving metals, including reflective materials like aluminum, copper, and brass.

- Nd:YAG and Nd:YVO Lasers: These crystal-based lasers are also solid-state and are used for both cutting and engraving a wide range of materials. They can operate at very high power, making them suitable for thicker materials.

What Materials Can Be Cut?

One of the most significant advantages of laser cutting is its versatility. It can be used on a vast array of materials, including:

- Metals: Steel, stainless steel, aluminum, brass, copper, and titanium.

- Plastics: Acrylic, polycarbonate, polypropylene, and PETG.

- Wood: Plywood, MDF, hardwoods, and softwoods.

- Fabric and Textiles: Leather, cotton, felt, and polyester.

- Paper and Cardboard: For intricate designs in packaging and art.

- Foam: For custom inserts and packaging solutions.

This wide range of compatible materials makes laser cutting a go-to solution for many fabrication needs.

Unmatched Precision and Its Advantages

The primary reason laser cutting has become so prevalent is its incredible precision. Modern laser cutters can achieve tolerances as tight as ±0.005 inches (0.127 mm), or even finer, depending on the machine and the material being cut. This level of accuracy allows for the creation of incredibly complex geometries and fine details that would be difficult or impossible to produce with other methods.

Advantages Over Traditional Cutting

Compared to conventional cutting methods like plasma cutting, waterjet cutting, or mechanical sawing, laser cutting offers several key benefits:

- Superior Edge Quality: Laser cutting produces a smooth, clean edge that often requires no further finishing. The heat-affected zone (HAZ) is typically very small, which minimizes material distortion, especially in thin sheets.

- High Speed and Efficiency: For many materials, especially thin sheets, laser cutting is significantly faster than other methods. The process is also highly automated, reducing labor costs and increasing throughput.

- Material Versatility: As noted earlier, lasers can cut a wide range of materials with a single machine, often just by adjusting the settings.

- Non-Contact Process: Because the laser beam is the only thing that touches the material, there is no tool wear. This reduces maintenance costs and ensures consistent cut quality over time.

- Complex Geometries: The focused beam allows for intricate patterns, sharp corners, and small holes that are challenging for mechanical tools.

Applications Across Key Industries

The precision and versatility of laser cutting have made it a vital technology in numerous sectors.

Medical Devices and Healthcare

In the medical field, precision is a matter of life and death. Laser cutting is used to produce a wide range of medical devices, from tiny stents and surgical instruments to custom orthopedic implants. The ability to work with biocompatible materials like titanium and create complex, burr-free components makes it an ideal choice.

Aerospace and Aviation

The aerospace industry relies on high-strength, lightweight materials that must meet strict quality standards. Lasers are used to cut components for aircraft engines, fuselage panels, and interior fittings from materials like aluminum alloys and composites. The precision of laser cutting ensures that parts fit together perfectly, which is critical for structural integrity and performance.

Electronics and Semiconductor Manufacturing

Laser technology is essential for manufacturing the miniature components found in modern electronics. It is used to cut silicon wafers for semiconductors, scribe circuit boards, and create tiny parts for smartphones and other devices. The non-contact nature of laser cutting is particularly important here to avoid damaging delicate electronic components.

Automotive and Transportation

In the automotive industry, laser cutting is used for everything from prototyping new vehicle designs to mass-producing parts. It provides the speed needed for high-volume production and the precision required for custom components. For businesses looking for metal fabrication services, laser cutting offers an efficient way to produce everything from chassis components to custom exhaust systems.

The Future of Laser Cutting

The field of laser cutting is continually evolving, with ongoing advancements pushing the boundaries of what is possible.

Advancements in Laser Technology

Researchers are developing more powerful and efficient lasers. Ultrafast lasers, such as picosecond and femtosecond lasers, can cut materials with virtually no heat-affected zone, enabling “cold ablation.” This is particularly useful for heat-sensitive materials and applications requiring the utmost precision.

Integration with Automation and AI

The integration of laser cutting systems with robotics and artificial intelligence is leading to fully automated production lines. AI algorithms can optimize cutting paths to minimize material waste and adjust cutting parameters in real-time to ensure consistent quality. This trend towards “smart manufacturing” is making laser cutting more efficient and reliable than ever.

Potential New Applications

As the technology improves, new applications are emerging. We may see laser cutting used more extensively in fields like architecture for creating custom building facades, in fashion for designing intricate textile patterns, and even in food processing for precise portioning.

Conclusion

Laser cutting technology represents a significant leap forward in manufacturing. Its combination of precision, speed, and versatility has made it an essential tool for industries that demand the highest standards of quality and performance.