Water damage remains one of the most persistent threats to building integrity, often starting invisibly and leading to costly repairs if left unchecked. SBS (Styrene-Butadiene-Styrene) modified bitumen waterproofing membranes have emerged as a trusted solution in modern construction, offering robust protection across diverse applications. At Great Ocean Waterproof, we’ve seen firsthand how properly applied SBS membranes extend structure lifespans and provide lasting peace of mind for property owners.

What is SBS Waterproofing Membrane?

SBS waterproofing membrane is a flexible, polymer-modified bituminous sheet designed for superior waterproofing performance. The SBS elastomer is blended into asphalt to create a material that remains elastic even in cold temperatures, unlike traditional bitumen which can become brittle.

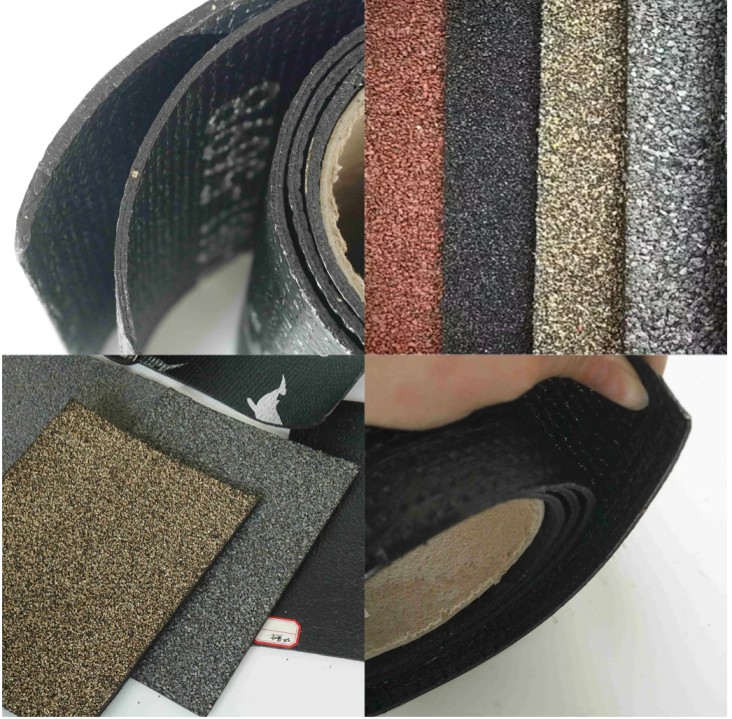

Typically reinforced with polyester or fiberglass carriers, these membranes come in thicknesses ranging from 2mm to 5mm. The top surface is often finished with mineral granules, ceramic-coated slate, or a smooth film, while the underside is engineered for specific installation methods—torch-applied, self-adhesive, or cold-process adhesive.

This combination of flexibility, strength, and adhesion makes SBS membranes particularly effective in environments subject to thermal movement, structural shifting, or extreme weather cycles.

Key Advantages of SBS Waterproofing Membranes

Several properties set SBS membranes apart from other waterproofing systems:

- Excellent low-temperature flexibility – They remain pliable down to -20°C or lower, reducing the risk of cracking during winter contraction.

- High elongation and recovery – Capable of stretching up to 300% without permanent deformation, ideal for structures that experience movement.

- Strong tear and puncture resistance – Reinforced carriers provide durability on busy roofs or below-grade applications.

- Proven longevity – Well-installed SBS systems commonly last 20–30 years with minimal maintenance.

- Versatile installation options – Available in torch-on, self-adhered, and cold-applied versions to suit different project requirements and safety considerations.

These characteristics make SBS a preferred choice for both new construction and renovation projects where long-term performance is non-negotiable.

Common Applications of SBS Waterproofing Membrane

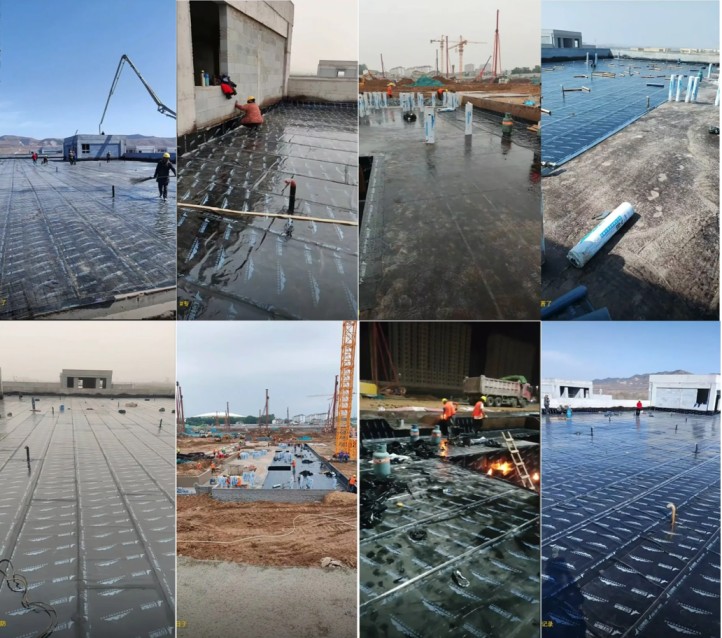

Flat and Low-Slope Roofing

SBS torch-on membranes are widely used on commercial flat roofs, industrial facilities, and residential low-slope designs. Their ability to create a fully adhered, monolithic barrier excels in areas with ponding water or heavy foot traffic.

Below-Grade Waterproofing: Basements and Foundations

In underground structures, SBS membranes provide positive-side waterproofing that prevents hydrostatic pressure from forcing water through concrete walls or slabs. Self-adhered or torch-applied sheets are commonly used, often in combination with protection boards and drainage mats.

Plazas, Podium Decks, and Balconies

Above occupied spaces, SBS membranes serve as the primary waterproofing layer beneath paving, landscaping, or wear courses. Multi-layer systems with root-resistant cap sheets are popular for green roofs and intensive landscaping.

Infrastructure: Tunnels, Bridges, and Parking Structures

Heavy-duty SBS membranes protect critical infrastructure from water ingress. Their chemical resistance and ability to bridge cracks make them suitable for bridge decks and tunnel linings where structural movement is expected.

Installation Methods and Best Practices

Successful application depends on proper technique and attention to detail. The most common methods include:

- Torch-Applied – The membrane is heated with a propane torch to melt the bitumen, creating a seamless bond to the substrate. Requires skilled applicators and strict safety protocols.

- Self-Adhered – Peel-and-stick sheets ideal for below-grade or sensitive areas where open flame is prohibited.

- Cold-Applied – Uses mastic or adhesive, suitable for complex details and smaller projects.

Regardless of method, surface preparation is critical: the substrate must be clean, dry, smooth, and primed. Overlaps should be at least 100mm on end laps and 75mm on side laps, with all seams fully sealed. Proper detailing around penetrations, drains, and upstands prevents the majority of leaks.

Multi-layer systems—base sheet plus cap sheet—provide redundancy and enhanced durability, particularly in high-exposure applications.

Conclusion

The application of SBS waterproofing membrane represents a mature, reliable technology that continues to evolve with improved polymers and sustainable formulations. When selected and installed correctly, it delivers decades of protection against water intrusion—one of the most destructive forces a building can face.

At Great Ocean Waterproof, we supply premium SBS membranes backed by technical expertise and field support. Whether you’re planning a commercial roof, residential basement, or infrastructure project, our team can help you choose the right system for lasting performance.

Contact us today to discuss your waterproofing needs.